From sand to granite, No Dig Equipment offers a wide range of back reamers for directional drilling, so you can maximize productivity in the hole no matter what the ground conditions are.

We build Long Life Backreamers

Directional drilling backreamers must combine hardness for long life and toughness for long term durability so that the tool does not fail under the normal back reaming forces.

A superior finish to the bored hole

Reaming should only remove small amounts of material in a progressive manner, this ensures a long life for the reamer and a superior finish to the bored hole.

No Dig Equipment provides a wide range of directional drilling HDD back reamers to suit all your trenchless jobs.

See details below for the range of HDD backreamers we can supply.

HDD backreamers designed for high mixing and pumping action in sticky clay ground conditions. Carbide cutters are precisely placed to provide smooth even cutting action.

| Ripper Reamer | |

| Part # | |

| Ripper Reamer 200mm Cut Diameter, 2 1/2" shaft | RR200 |

| Ripper Reamer 250 mm Cut Diameter, 2 1/2" shaft | RR250 |

| Ripper Reamer 300 mm Cut Diameter, 2 1/2" Shaft | RR300 |

| Ripper Reamer 350 mm Cut Diameter, 2 1/2" shaft | RR350 |

| Ripper Reamer 400 mm Cut Dia, 2 3/8 API shaft | RR400 |

| Ripper Reamer 500 mm Cut Dia, 2 3/8 API shaft | RR500 |

Don’t forget the Connector Subs and Swivels

Exceptionnal reamer for clay and mixed ground.

Download our catalogue NOW, and receive a special discount on this reamer.

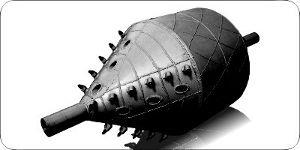

| Rock Reamer | |

| Part # | |

| Reamer Hole Opener | RHO200 |

| Reamer Hole Opener | RHO300 |

| Reamer Hole Opener Medium Hard IADC 537 | RHO400 |

| Reamer Hole Opener Medium Hard IADC 537 | RHO500 |

See the Connector Subs and Swivels

Rock Reamer – Hole Opener

Custom built rock reamers for back reaming in rock to 200 MPa. Soft and hard formation cutter options available. Reamers can be configured with built-in stabilizer for single package reaming.

See more Hole Opener options here

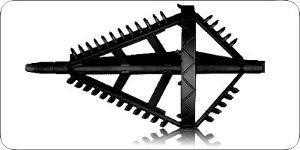

Fly Cutter

Our Fly Cutter Back Reamers are ideal for mixed ground conditions, large openings allow cobbles to pass with great mixing action.

Ideal for clay and abrasive soil conditions

Find our complete selection of back reamer in the HDD Tooling Catalogue – Available NOW!

| Fly Cutter | |

| Part # | |

| Fly Cutter 300mm Diameter Cut Size | RF300 |

| Fly Cutter 400mm Diameter Cut Size | RF400 |

| Fly Cutter 500mm Diameter Cut Size | RF500 |

| Fly Cutter 600mm Diameter Cut Size | RF600 |

| Fly Cutter 700mm Diameter Cut Size | RF700 |

See the Connector Subs and Swivels

| Compaction Reamer | |

| Part # | |

| 115mm Pack, 2 1/2" shaft, (Optional Swivel) | RC115 |

| 150mm Pack, 2 1/2" shaft, (Optional Swivel) | RC150 |

| 200mm Pack, 2 1/2" shaft, (9T Built in Swivel) | RC200 |

| 250mm Pack, 2 1/2" shaft, (9T Built in Swivel) | RC250 |

| 300mm Pack, 2 1/2" shaft, (9T Built in Swivel) | RC300 |

| 350mm Pack, 2 1/2" shaft, (9T Built in Swivel) | RC350 |

| 400mm Pack, 2 3/8 API through shaft | RC300 |

| 500mm Pack, 2 3/8 API through shaft | RC500 |

| 600mm Pack, 2 3/8 API through shaft | RC600 |

| 650mm custom build, Check out the pictures on Facebook, click here | RC650 |

Don’t forget the Connector Subs and the Swivels

Reduce torque on the drilling process!

Install the pipe in one go and don’t get stuck

Compaction Reamer

Our new Compaction Back Reamer suite a great variety of ground conditions from wet running sands through to hard abrasive ground. Ballistic carbide cutters provide great grinding action in harder ground.

This reamer is Ideal for sandy mixed ground conditions and with its unique troweling edge promotes a superior bentonite filter cake which aids in-hole support and reduces pressure to aid flow-out of cuttings.

More on our Compaction Reamers here

Barrel Reamer

Our barrel back reamer is the standard for larger HDD rigs, come with API threads and back cutters for back or forward reaming.

Ideal for sand and loam soil conditions, the barrel reamer can be used for stacking with fly cutter of hole opener, or can be used by itself for cleaning pre-reamed holes and pulling in the product.

| Barrel | |

| Part # | |

| Barrel Reamer 2 3/8" API reg, 300mm Dia pack size | RB300 |

| Barrel Reamer 2 3/8" API reg, 400mm Dia pack size | RB400 |

| Barrel Reamer 3 1/2" API reg, 500mm Dia pack size | RB500 |

| Barrel Reamer 3 1/2" API reg, 600mm Dia pack size | RB600 |

See our Quick Connector Subs & Swivels

Because every job is different, No Dig Equipment only manufacture the HDD Reamer Stabilizer to order. This is to ensure that the stabilizer perfectly matches the package to be installed.

See the Connector Subs and Swivels

HDD Reamer Stabilizer

HDD back reamer stabilizers or centralizers ideally run in conjunction with hole openers, fly cutters & barrel reamers. They provide support in front or behind the reamer to ensure that hole is cut central and straight.

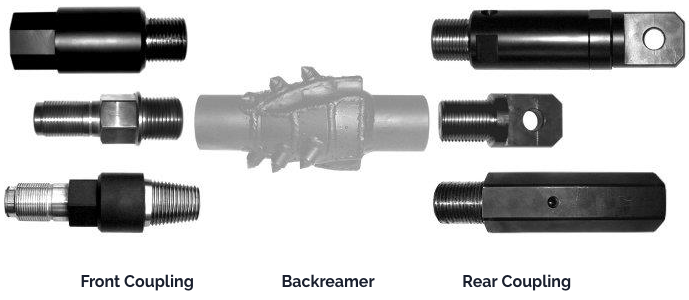

No Dig Equipment manufacture connector subs / adaptors compatible with most common Vermeer and Ditch Witch HDD Drill Rigs. Our adaptors are specifically designed to match our backreamers. They provide an easy solution to

This also provides a very cost effective solution for repairing your backreamer, as it is usually the front thread that wears out prematurely. With the use of a cheap replaceable adaptor, you can be backreaming fast.

For a complete range of our adaptors please have a look at the the table below. Other connector subs / adaptors and crossover subs are available on request.

| Connector Subs - Front Coupling | |

| Adaptors to suit Vermeer® HDD Drills | |

| D7x11, suits 2.1/2" Shaft | RSV711-50 |

| D16x20, D20x22, D24x40, to suit 2.1/2" Shaft | RSV2440-50 |

| D16x20, D20x22, D24x40, to suit 3" Shaft | RSV2440-100 |

| D16x20, D20x22, D24x40, to suit 2.3/8" API Reg thread | RSV2440-API |

| Other sizes of thread on request | |

| Adaptors to suit Ditch Witch® HDD Drills | |

| JT1720, JT2020, JT2720, to suit 2.1/2" Shaft | RSD2020-50 |

| JT1720, JT2020, JT2720, to suit 2.3/8 API Shaft | RSD2020-API |

| Connector Subs - Rear Coupling | |

| Pulling eye | |

| 20-ton, suits 2.1/2" Shaft | RSP-50 |

| 40-ton, suits 2.3/8 API Shaft | RSP-API |

| Swivel to suit Vermeer® HDD Drills | |

| Adaptor sub suit 2.1/2" Shaft | RSVQ-50 |

| Adaptor sub suit 2.3/8 API Shaft | RSVQ-API |

Copyright © 2024 No Dig Equipment. All Rights Reserved.